In a new build:

The UK government has ruled that gas boilers will be banned in all new homes built after 2025, as part of the Future Homes Standard, designed to tackle climate change, it requires new builds to have low carbon systems like heat pumps and aims to reduce carbon emissions by 75-80% compared to current standards. Starting in 2021, all new build homes are expected to achieve a 31% reduction in carbon emissions. From 2025, it will be mandatory to fit low carbon heating systems in new buildings, making homes more energy-efficient with solutions such as insulation and heat pumps. This ruling is part of the government’s ten-point initiative to help the UK reach its target of net zero carbon emissions by 2050.

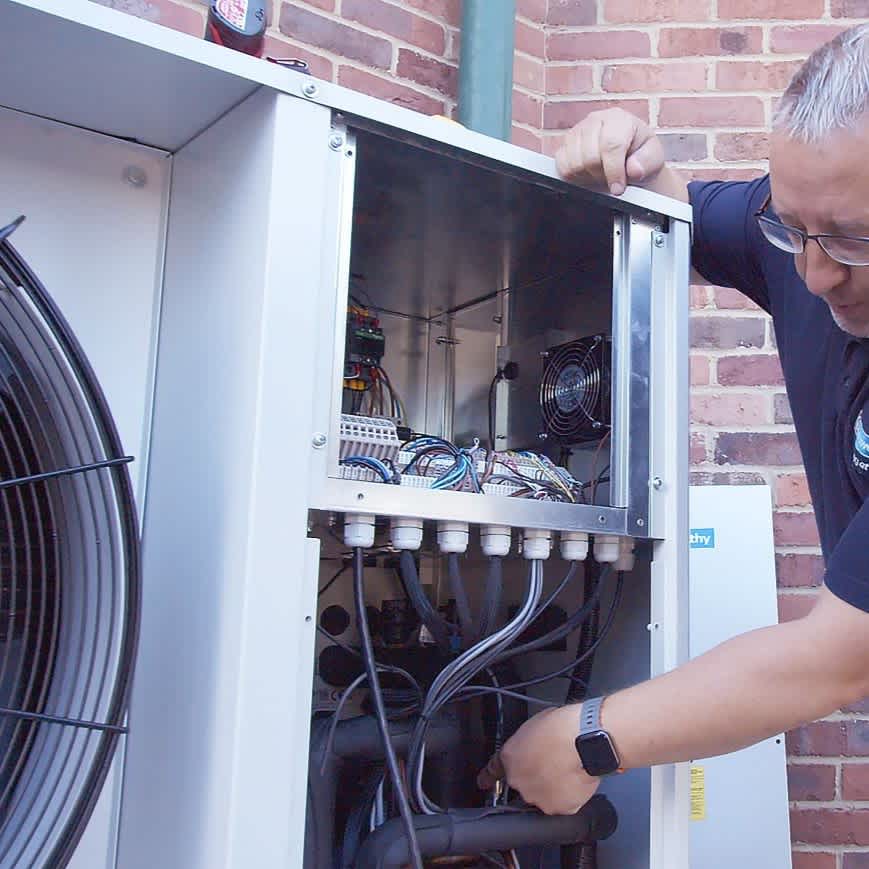

In plant room replacements there may be more reasons to install a commercial air source heat pump:

To qualify for the government schemes that require low carbon technology

Schemes such as the public sector decarbonisation scheme require your client’s project to install low carbon heat systems such as air source heat pumps in order to achieve the sustainability requirements and be awarded funding. Air source heat pumps are an effective low carbon heating solution for large projects.

To meet business carbon targets

Using heat transfer principles, air source heat pumps are carbon neutral which means they do not produce any greenhouse gas emissions. For businesses looking to improve their carbon footprint or meet ambitious carbon targets, heat pumps can help them by reducing the carbon emissions generated from their heating and hot water.

To be as green as possible and/or reduce reliance on gas-powered technologies

If you’re concerned about your operation’s carbon footprint and want to adopt low or zero carbon heating, installing a heat pump could meet your sustainability goals.

When simply comparing the unit cost, electricity is currently 3-4 times more than the cost of gas, however this doesn’t factor in the costs of installation, maintenance, lifespan and most importantly, energy efficiency which in turn influences running costs. Heat pumps generally have lower running costs than gas boilers because of their higher energy efficiency.

As heat pumps are effectively extracting ‘free energy’ this can create very high efficiencies as the energy extracted is greater than the energy used to drive the heat pump. This means the running cost of the heat pump is considerably less than a gas boiler.

So whilst the initial setup costs of a heat pump might be more significant than that of a gas boiler, in the long-term, heat pumps could provide a more efficient and cost-effective heating solution.

To change from oil or LPG to electric

If you’re replacing an oil or LPG system and aiming to cut running costs, a heat pump delivers more heat per unit of electricity than conventional oil/LPG boilers.

To future-proof a building

With the UK targeting net zero emissions by 2050 and tighter energy-efficiency regulations imminent, a heat pump ensures long-term compliance and resilience to evolving energy requirements.

Further reading: