Combining heat pumps with traditional gas boilers in commercial refurbishment projects

The construction and operation of commercial buildings account for approximately 38% of global carbon emissions. Therefore, transitioning to heat pumps is a crucial step in our efforts to decarbonise these buildings and achieve Net Zero targets. While the focus on decarbonising heating has primarily emphasized replacing gas boilers with heat pumps, retrofitting heat pumps - especially in older or larger commercial buildings—can be challenging. In this article, we will explore the design considerations for installing heat pumps and discuss how hybrid systems can serve as a practical first step toward decarbonisation.

Maximising system performance

When designing a heat pump system in any commercial building, the crucial first step should be about reducing heat demand. This process involves conducting an energy audit to identify areas where heat loss can be minimised through improved insulation, sealing leaks, and optimising existing heating systems. By lowering the overall heat demand, efficiency can be enhanced, leading to reduced energy consumption and operational costs. Understanding heat demand will also help confirm the size of the heat pump needed for the system. Once this information is in place, you will also need to design a system which meets the expectations of the customer.

With heat demand, system requirements, and client expectations in place, it is then possible to select the appropriate heat pump technology. This could be a standalone heat pump, a heat pump cascade, or a hybrid system.

Understanding a hybrid heat pump system

As we seek to find more energy efficient, cost-effective, and sustainable heating solutions, commercial hybrid heat pump systems have become increasingly popular due to their ability to combine the energy efficiency of heat pumps with the proven track record of traditional heating methods, such as condensing gas boilers.

In a commercial hybrid heat pump system, the heat pump serves as the primary method for heating the building, handling the majority of the load, with a boiler serving as the secondary heat source. So, let’s explain how this works.

Heat pumps operate by transferring heat from one location to another instead of generating heat directly. In heating mode, the heat pump extracts warmth from the outside environment—whether from the air, water, or ground—and uses it to warm the interior of the building. This process is significantly more energy-efficient than traditional heating systems that burn fossil fuels, making heat pumps an environmentally friendly and cost-effective solution.

However, a challenge arises during peak winter conditions when outdoor temperatures can drop significantly. In these conditions, heat pumps work harder to extract enough heat from the air when temperatures fall below a certain threshold (typically around 4°C or lower). As a result, their efficiency drops, and they may not be able to efficiently meet the building's heating needs on their own.

This is where the boiler in the hybrid system comes into play. The boiler provides the necessary supplementary heat which the heat pump can efficiently handle alone. Once outdoor temperatures rise again, the hybrid system will automatically switch back to using the heat pump as the primary source of heating. As the boiler, usually powered by natural gas, oil, or electricity, is only activated when needed, this ensures that the building remains comfortably heated without unnecessary energy consumption.

Cascading wall-hung commercial condensing boilers, such as the Stratton Mk3, or floor-standing modular models such as the Modumax Mk3, are ideal for a hybrid system as a higher modulation is achieved, so gas usage is far more efficient. With a large single boiler, it would cycle on and off, using considerably more fuel than necessary. This hybrid system can also be integrated seamlessly with a commercial air source heat pump, such as the Tyneham.

In a slight variation on this, heat pumps can also be configured to supply heating exclusively to the radiators, while gas boilers are retained for domestic hot water (DHW) production. In this arrangement, the heat pump and gas boiler operate alongside each other rather than together. This setup has several advantages. By eliminating the need for high-temperature generation from the heat pumps, they can efficiently function at stable, low temperatures for extended periods. Furthermore, as this also enables a reduction in the size of the heat pump, as well as minimised pipework and thermal storage requirements, significant cost savings can be achieved. This is particularly important for projects with limited funding that do not allow for upgrades.

As different customers have different needs, selecting the right approach and configuration for a hybrid heat pump set up is important. Whilst some customers may be focused on upfront costs, others might prioritise long term savings in energy bills etc, so selecting a suitable system that balances both short and long term benefits for the customer is a priority. Additionally, it’s important to consider that the customer may also have goals relating to sustainability, such as reducing their carbon footprint or lowering energy consumption.

When to choose a hybrid system

Whilst condensing gas boilers are well-known for their ability to quickly and effectively heat large spaces, it’s no secret that air-source heat pumps provide a more efficient and low-carbon alternative, which is a particularly important consideration for building owners who strive to reduce their carbon footprint and embrace more sustainable practices. But what about commercial buildings that are not yet ready to completely rely on heat pumps alone?

We all know that low-carbon technologies, such as heat pumps, perform best in well-insulated buildings and at low operating temperatures. So, when it comes to older or larger buildings with high demands, which often have older heating and hot water systems that operate at higher temperatures, poor insulation, or space restrictions, standalone air source heat pumps might not necessarily be the best way forward.

To tackle these limitations, one approach could be to deploy a hybrid heat pump system that combines high-efficiency new or existing condensing gas boilers or water heaters with an air source heat pump (ASHP).

Hybrid heating in action

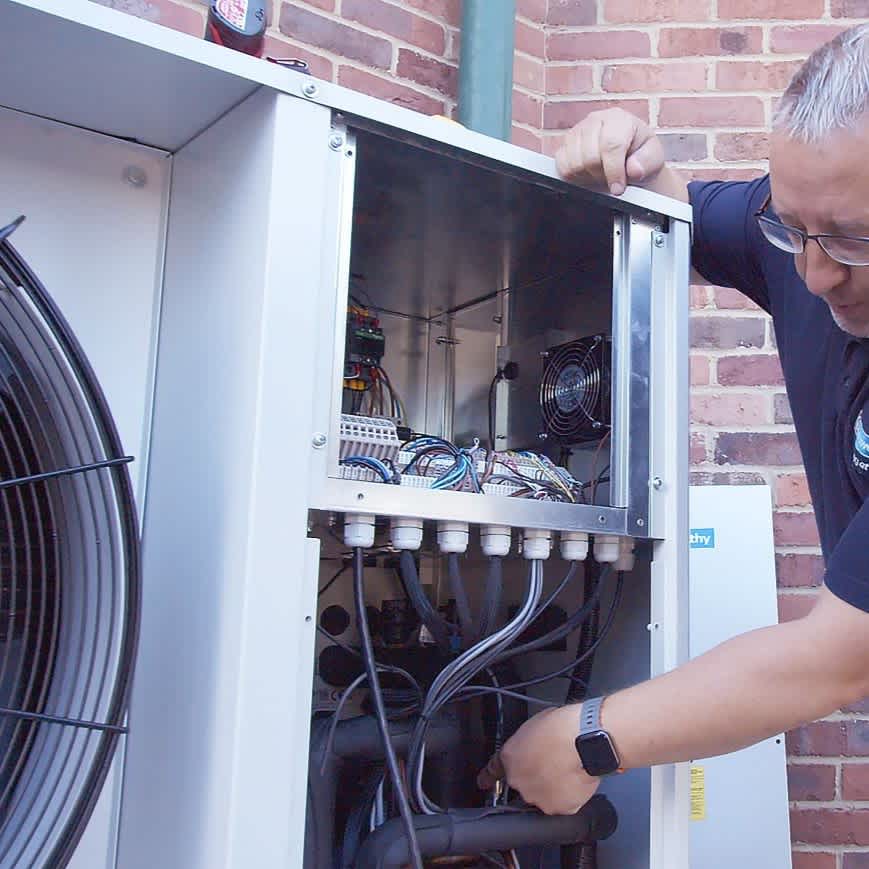

As part of its commitment to reduce energy use across council-run buildings in Sunderland, Stansfield Business Centre in Sunderland has taken this hybrid approach. They have installed a 32kW Tyneham air source monobloc heat pump, connected to a 500L buffer cylinder. This has been installed alongside a Stratton Mk3 condensing wall-hung boiler, for a low-carbon hybrid heating system, offering year-round reliability and comfort and lower running costs. Controlled by a BMS system, which can be accessed on-site or remotely, Sunderland Council is now able to conveniently and simply manage the system, as and when required. Following the upgrade, Stansfield Business Centre now benefits from an energy-efficient hybrid heating system, which has enabled Sunderland Council to further reduce its carbon impact.

Easy to integrate

One significant advantage of installing hybrid systems in older commercial buildings is that they can usually work with existing heating setups. They also require minimal modifications. This makes them a practical and cost-effective option, especially for those facing urgent heating and water issues due to a failed boiler. Moreover, as they can be easily adapted to suit various changes in building size and demands, this makes them a versatile solution for commercial buildings, such as schools, care homes, and other settings where significant disruption could negatively impact building occupants.

Conclusion

Hybrid heating systems help bridge the gap between reliance on fossil fuel-burning boilers and low-carbon heat pumps and enable buildings to move towards decarbonisation at a more affordable price tag.

That being said, the capital cost of heat pumps is more in comparison to gas boilers and despite their efficiency, running costs are not lower due to the price of electricity compared to gas in the UK. These costs remain a stumbling block for many and if budgets are limited, many building owners may be forced into replacing one fossil fuel system with another, albeit a more energy-efficient condensing boiler, such as the Modumax Mk3 stainless steel high efficiency, fully modulating condensing pre-mix floor standing boiler.

Additionally, whilst hybrid heating systems can without doubt also reduce carbon emissions by up to 80%, which is an important consideration for business owners trying to meet environmental targets, many condensing gas boilers on the market today now offer up to 90% efficiency. This, coupled with so much uncertainty on the government's plans to ban the installation of gas boilers from 2035, still leaves modern condensing boilers in a very strong position within the marketplace.

Whilst a hybrid heating system can, without doubt, break down the barriers for buildings looking to upgrade or replace existing systems with no or low carbon heating technology, understanding the end goal for retrofitting heat pumps and boiler replacements, together with the practical installation and running costs, is key when deciding to upgrade an existing boiler set up or design a hybrid boiler and heat pump system.

The right solution for the right building

At Hamworthy, we know that no two projects are the same. That’s why we offer tailored technical advice, expert knowledgeable support and a full range of products developed specifically for a wide range of commercial heating applications.

To assist you in this process, we have free Continuing Professional Development (CPD) seminars. Our CIBSE approved CPD “Considerations for air source heat pumps selection, specification and system design” covers this topic and can be booked by speaking with your Hamworthy Area Sales Manager.

Alternatively speak to your Hamworthy Area Sales Manager for a site survey on your next project.