Why is the refrigerant important when selecting a heat pump?

Refrigerants are an essential component to the efficient running of heat pump systems, but with so many types to choose from - each with a formulaic name of their own - it can be confusing and difficult to see how specifying the right heat pump system with the right refrigerant matters for your heating project.

Do refrigerants matter when specifying heat pumps?

By understanding how refrigerants work within a heat pump – boiling from a liquid into a vapour and then condensing back into a liquid state – you can better understand how the environment and external factors can influence the efficiency, effectiveness and running costs of a heat pump’s operation. In turn, the type of heat pump system you specify may then be influenced by which type of refrigerant it runs on.Specifying a heat pump without factoring in what type of refrigerant it uses could be very costly if the refrigerant itself is very expensive to replace/maintain. It can also affect the efficiency of the heat pump if the refrigerant has to work harder and rely on additional energy input, which in turn may lead to higher running costs.

Whilst not exhaustive, here are three key factors for consideration when looking at the wide range of heat pump refrigerants.

The outside air temperature

In the first part of the reverse Carnot cycle process, the refrigerant absorbs the heat in the outside air (or external energy source). This means that the refrigerant needs to have a much lower temperature than the outside air so that it can maximise the amount of energy that it absorbs, as it boils. The higher the temperature difference between the refrigerant and the external energy source, the faster it can boil, resulting in more efficient heat transfer indoors.

So, the first factor for consideration should be understanding the impact of the ambient air temperature (for an air source heat pump, for example) on the refrigerant’s ability to absorb and transfer heat. If the average ambient air temperature is cooler than normal, you may need to consider a refrigerant with a lower boiling point so that the heat pump doesn’t have to work as hard or rely on additional input from the grid (where electricity can cost over three times more than gas). This is known as the Coefficient of Performance (COP) or Seasonal Coefficient of Performance (SCOP) when factoring in the changes of the environment throughout the year.

The flow and return temperature

You also need to fully understand the flow and return temperatures needed and whether the refrigerant you are considering can meet the requirements of the heating project. For example, some refrigerants may not be able to generate the temperatures required for large volumes of domestic hot water (DHW) or commercial applications. However, with the right refrigerant, heat pumps can generate temperatures up to 75ºC, which, when compared to gas boilers, can make for a much better commercial solution.

In addition to factoring in the temperature required, a heat pump that generates a high delta temperature (delta T), or temperature differential, means that the temperature of the return water is significantly colder than when it left the heat pump (so that it can boil again more efficiently). The delta T will influence the system design supporting the heat pump, for example, whether pipework will need to be adjusted if the delta T is too low (the temperature returned is too high); as well as how much heat loss is seen from the return pipe.

The type of refrigerant used will influence the temperature differential and so needs to be considered. A synthetic refrigerant e.g., R134a, for example, will typically produce a lower delta T, whilst natural refrigerants e.g., R744 will produce higher delta Ts.

Specifiers will therefore need to find the balance between the temperatures required of the heat pump and how big (or small) the temperature differential is.

The environmental impact

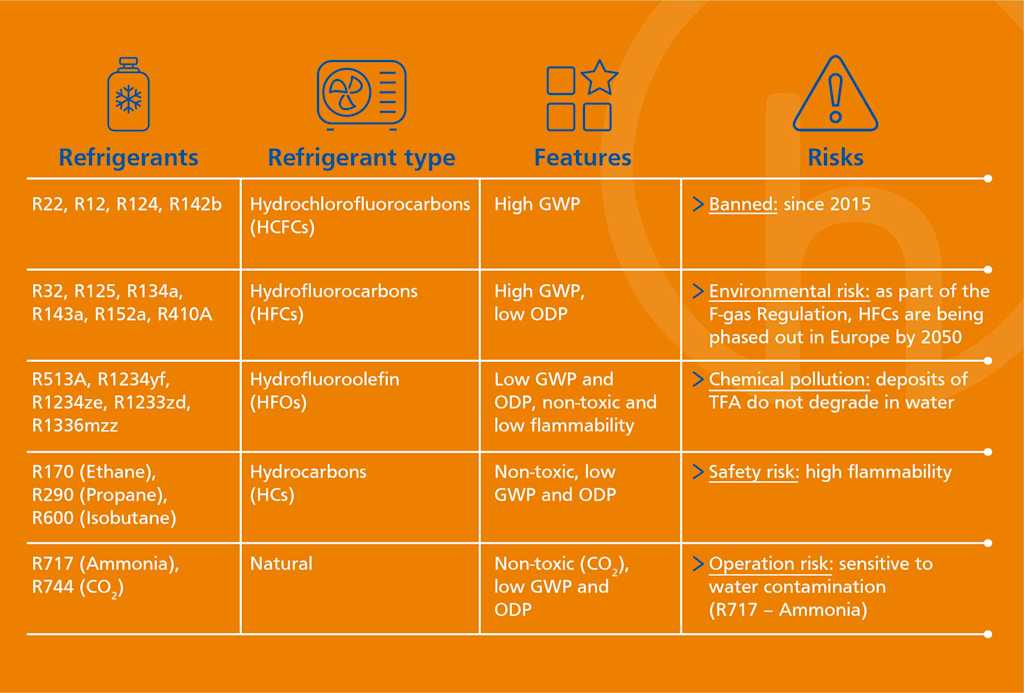

Heat pumps are typically specified as a low carbon heating technology of choice to help reduce a building’s carbon footprint, as they utilise ‘free’ energy from the external environment. However, the refrigerant used itself can influence how carbon neutral the heat pump system ends up being. The environmental impact of refrigerants is assessed by three factors:

Ozone Depletion Potential (ODP) – a measure of how much damage to the ozone layer is caused compared to trichlorofluoromethane (R11)

Global Warming Potential (GWP) – a measure of its contribution to global warming compared to CO2

And Total Equivalent Warming Impact (TEWI) – the sum of direct and indirect greenhouse gas emissions from heat pumps

Specifiers will often focus on how low of a GWP a heat pump has, as typically the lower the GWP, the lower the carbon footprint of the overall heating system. This, like the temperature generated by a heat pump, can be influenced by the choice of refrigerant; but understanding the TEWI of a heat pump can help provide a more rounded picture of the environmental impact of a heat pump system. Because TEWI looks at both direct and indirect emissions, it can factor in refrigerant leakage and the energy supply required to run the system over its lifetime. Calculating the TEWI of a heat pump system design might highlight where the refrigerant is not working effectively or flag that the supporting heating system isn’t compatible. So, by having this bigger picture, specifiers can make an informed decision in both selecting the right heat pump for their project and ensuring they are using the right refrigerant to make the system as efficient and cost-effective to run as possible.

Simplifying the choice of many

Being aware of some of these factors and their implications should make specifying the right heat pump with the right refrigerant for your heating project simpler as you understand better what to look for when navigating a sea of ‘Rs’.

The use of R744 – CO2 refrigerants – is becoming increasingly popular. This is because, as a natural refrigerant, it has a very low GWP and ODP, whilst also being non-toxic and non-flammable. Most importantly, it has a much higher heat transfer efficiency than other refrigerants.

CO2 refrigerants are here for the long run, unlike other refrigerants being phased out by legislation. Heat pumps that use R744 will not need to reconsider the type of refrigerant it runs off further down the line, as has been seen with HVAC equipment using the now-banned refrigerant R22. It is also a much cheaper refrigerant to replace and maintain, which is another factor to consider when calculating the running costs of a heat pump.

This is why Hamworthy is launching the latest addition to its air source heat pump (ASHP) range – the Tyneham 290HT 15Kw-50kW Tyneham CO2/CO2Q 65Kw-130kW. This complements our existing Tyneham ASHP, utilising R32 as a refrigerant, which offers advantages such as a lower GWP, improved energy efficiency, and simplified recycling processes.

Want to know more?

Hamworthy is proud to play a part towards the UK’s target of net zero emissions by 2050 and help the industry decarbonise commercial heating applications. To find out more, ask for technical advice, or to discuss how Hamworthy can help you with specification, get in touch with your Area Sales Manager.